In the packaging industry, bubble film (also known as air bubble film) has become an indispensable material for protecting fragile goods during transportation and storage. Behind the mass production of this versatile packaging solution lies a key piece of equipment: the bubble film machine. This guide delves into its fundamentals, including definition, working principles, investment benefits, and conclusion.

A bubble film machine is specialized industrial equipment for producing bubble film—a flexible packaging material with air-filled bubbles that cushion and protect fragile items like electronics, glassware, and furniture. It comes in various types, categorized by output capacity (hundreds of kg to tons per day), film width (narrow to industrial-wide), and plastic material (mostly polyethylene like LDPE, LLDPE). Advanced models offer adjustable bubble size, multi-layer production, and automatic controls for customization.

Its working process involves sequential steps to form the bubble structure:

Raw Material Feeding and Melting: Polyethylene resin pellets are fed into the extruder. The rotating screw conveys pellets forward, and barrel heaters melt them into molten plastic with precise temperature control to avoid degradation.

Film Extrusion: Molten plastic is pushed through a circular die head to form a continuous tubular film ("bubble"), whose initial diameter depends on the die head size.

Bubble Blowing and Cooling: Compressed air is injected into the tube to expand it into a bubble. Cooling devices (air rings/water baths) solidify the plastic—air amount controls bubble size, and cooling rate affects film thickness and properties.

Traction and Flattening: Traction rollers pull the cooled bubble upward (controlling film thickness) and flatten it into a double-layer film with trapped bubbles.

Winding: The flattened film is wound into tight, uniform rolls for storage, cutting, or direct use.

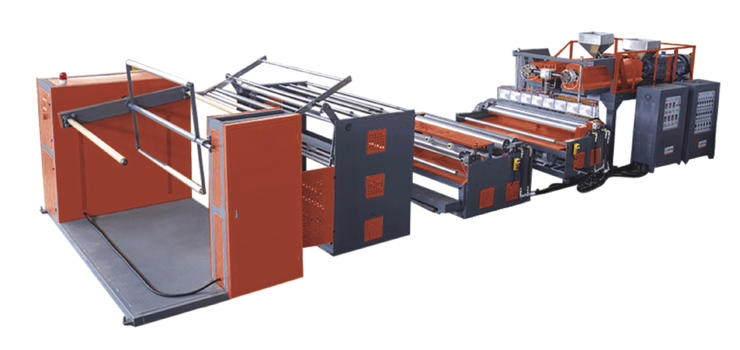

YHPIEG-7LB fully Automatic Air Bubble Film Machine has excellent performance and can produce up to 7 layers of bubble film at a speed of up to 25 meters/minute, producing high-quality finished products. It uses LDPE and LLDPE particles as raw materials, and independently and accurately controls the film layer and the bubble layer.

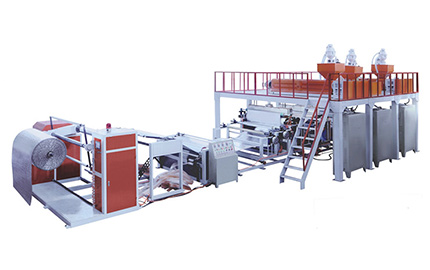

YHPEG-4LC high-speed bubble film machine uses LDPE and LLDPE as raw materials, is fully automatic PLC controlled, and can reach a speed of 30m/min. It can produce 2-4 layers of bubble film and is suitable for processing a variety of materials. It is efficient and intelligent, and is an ideal choice for bubble film production.

YHPE-ZLB Double Layer Bubble Film Machine adopts a twin-screw design, which can independently control the bottom layer and the bubble layer. It is easy to operate and fast, with fully automatic PLC control, which greatly reduces labor costs and significantly improves production efficiency.

Investing in it brings significant advantages for packaging businesses or those with large packaging needs:

Cost Savings: In-house production replaces external purchases—raw resin is more cost-effective, and bulk buying further reduces expenses, especially for high-volume users.

Market Adaptability & Customization: Tap into high demand across e-commerce, electronics, and logistics; offer customized film (size, thickness, color, print) to boost competitiveness.

Production Flexibility: Adjust output per demand to avoid inventory shortages/excesses; control production for consistent quality and timely delivery.

Long-Term ROI: Despite initial investment, long service life brings steady cost savings or new revenue streams (selling to other businesses).

Easy Operation: User-friendly controls suit basic-trained staff; routine maintenance (cleaning, lubrication, part replacement) is simple.

The bubble film machine is vital for efficient, cost-effective bubble film production, critical for goods protection in transit. Its sequential steps balance simplicity and efficiency, and investing offers cost savings, customization, flexibility, long-term ROI, and ease of operation.

Whether a small business cutting packaging costs or a large enterprise expanding portfolios, it’s a valuable asset. Leveraging it enhances packaging solutions, meets customer demands, and drives sustainable growth in the competitive packaging industry.