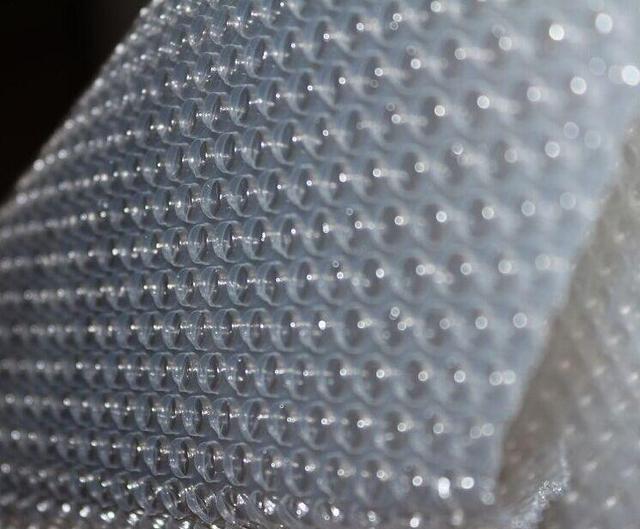

Bubble Film Machine is a mechanical device used to produce bubble film (also known as air cushion film, air bead film, bubble cloth, bubble paper, etc.). This device uses a specific process to heat and melt the plastic raw materials, extrude and blow them through a mold into a film with a bubble structure. Bubble Film Machine is widely used in packaging, logistics, electronics, home appliances and other fields.

The Bubble Bag Making Machine shines across key packaging scenarios—e-commerce (safeguarding electronics, cosmetics, fragile goods), logistics (cushioning parcels), manufacturing (wrapping precision parts), and retail (securing glassware/gifts). It adapts to PE/LDPE bubble films and crafts custom-sized bags (small pouches to large sheets), fitting diverse product needs seamlessly.

Its standout functions drive efficiency: 100-300 bags/min cuts labor costs, while auto feeding/sealing/cutting/counting slashes human error. Energy-saving low-power motors reduce electricity use by 15%, and adjustable sealing strength ensures airtight protection. With a user-friendly touchscreen and durable blades for long-term stability, it boosts productivity while guaranteeing top-tier bubble bag quality for all packaging demands.

Plastic Bag Making Machine is a mechanical equipment specially used to produce plastic bags of various specifications. Our company's Plastic Bag Making Machine can realize automatic production, adjustable size and thickness, adapt to different plastic materials, and has high production efficiency. Plastic bag making machines are widely used in the food industry, retail industry, daily necessities and other fields, providing enterprises with fast, flexible and cost-effective production solutions.

Film Blowing Machines are used to produce plastic films of different properties, thicknesses and widths. The production speed can reach 400KG per minute. The adjustable film thickness and width range and advanced control system make it a key equipment in plastic film production.

Stretch Film Making Machine can efficiently produce stretch film with excellent tensile properties and tear resistance. It has an advanced production control system to ensure that the films produced have consistent quality and performance, providing important packaging solutions for various industries.