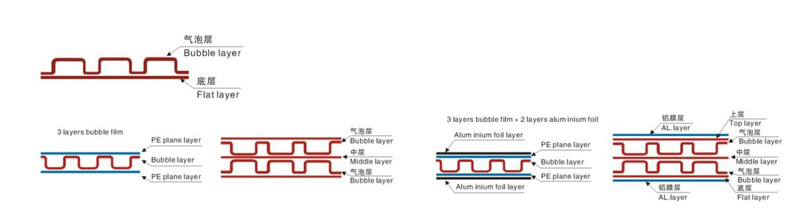

The YHPIEG - 7LB fully automatic air bubble film machine in China is an outstanding piece of equipment. It is capable of producing up to 7 layers of bubble film, which consists of 5 layers of bubble film and 2 layers of PET aluminum film. Moreover, it can be compounded with a variety of materials, such as kraft paper, pearl cotton, PET aluminized film, and co-extrusion film. With a high production speed, this machine can meet the demands of mass production.

1.Production Process:The manufacturing process includes extrusion, molding, traction, and coiling. Its unique mechanisms ensure efficient operation.

2.Cooling System:It is equipped with both air and water cooling systems.

3.Raw Materials:It supports LDPE (Low-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) particles as raw materials.

4.Screw Design:The main extruder features a twin-screw design, allowing for independent and precise control of the film layer and the bubble layer. This gives users the flexibility to adjust the product performance according to different needs.

5.Bubble Adjustment:By simply replacing the flower roller, the size and style of the bubbles can be easily changed to meet various packaging requirements.

1. Performance Advantages:The bubble film produced by this machine has multiple excellent properties, such as waterproofing, pressure resistance, anti-static, and heat insulation.

2. Application Areas:It is widely used in numerous packaging industries, including furniture, hardware, building materials, electronics, and express delivery.

3. Specification Options:Our machines are available in various specifications and molds to meet different needs.

4. Production Advantages:The production process is stable, with neatly arranged bubbles. The operation is easy and environmentally friendly, making it a cost-effective choice for enterprises dealing with fragile items.

5. Structural Diversity:It can not only produce single and double-layer films but also achieve more complex multi-layer structures, providing comprehensive packaging solutions.

|

Model |

Max. Width |

Screw Diameter |

Screw L:D |

Extruder MotorPower |

Take-up Motor Power |

VacumPump |

Speed |

Power |

|

YHPEG-1200 |

1200mm |

Φ65/55mm Φ65/55mm Φ50mm |

34:1 |

18.5/11 kw 18.5/11kw 11kw |

1.5kw |

1.1kw |

5-25m/min |

170kw |

|

YHPEG-1500 |

1500mm |

Φ70/60mm Φ70/60mm Φ55mm |

34:1 |

22/15 kw 22/15kw 15kw |

2.2kw |

1.5kw |

5-25m/min |

210kw |

|

YHPEG-1800 |

1800mm |

Φ75/60mm Φ75/60mm Φ60mm |

34:1 |

30/18.5 kw 30/18.5kw 15kw |

2.2kw |

1.5kw |

5-25m/min |

235kw |

|

YHPEG-2000 |

2000mm |

Φ80/65mm Φ80/65mm Φ65mm |

34:1 |

30/18.5 kw 30/18.5kw 18.5kw |

2.2kw |

2kw |

5-25m/min |

268kw |

|

YHPEG-2500 |

2500mm |

Φ85/70mm Φ85/70mm Φ70mm |

34:1 |

37/22kw 37/22kw 22kw |

3kw |

2.2kw |

5-25m/min |

300kw |

|

YHPEG-3000 |

3000mm |

Φ95/80mm Φ95/80mm Φ75mm |

34:1 |

45/30kw 45/30kw 30kw |

3kw |

3kw |

5-20m/min |

340kw |

|

YHPEG-3500 |

3500mm |

Φ110/90mm Φ110/90mm Φ85mm |

34:1 |

55/45 kw 55/45kw 37kw |

3kw |

3kw |

5-20m/min |

380kw |

*We willno longer inftorm you if there is any data change.

1. Chiller

2. Automatic Vacuum Feeder

3. Auto Changing Sieve

4. Blender

5. Scrap Reverse

6. Grinder

7. Auto Rewinder

8. In line perforated unit

9. Huangyan T-die