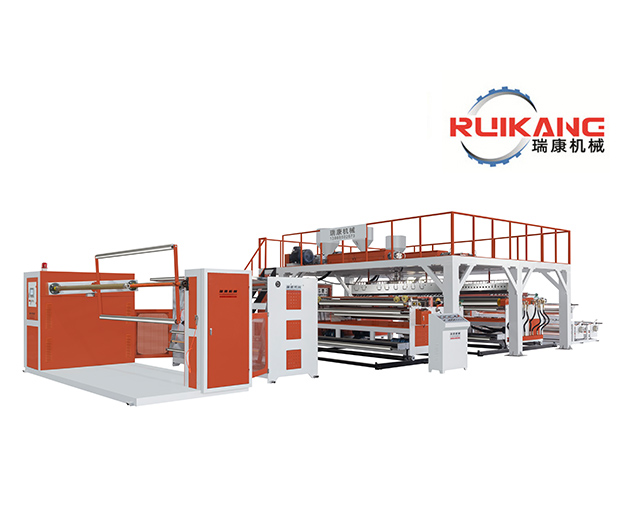

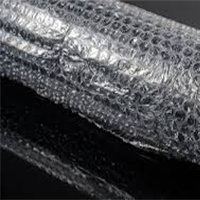

This air bubble film machine uses polyethylene as raw material and continuously produces air bubble film through an extrusion process. It utilizes an air layer to provide cushioning, offering shock, moisture, and pressure resistance. It can replace traditional fillers and is suitable for mailing valuables, cosmetics, small appliances, and fragile items. The film is also widely used in packaging and protection of precision instruments, handicrafts, auto parts, ceramic glass, fire-fighting equipment and furniture.

Supports LDPE, LLDPE and recycled materials; can add antistatic agents and other functional materials to meet differentiated needs in multiple fields.

Width 1000–3500mm, speed 5–30m/min; supports single/double-layer, antistatic films, with single or multi-die head options.

Adopts full PLC control with automatic winding, thickness adjustment, and feeding; intuitive interface ensures easy operation and monitoring.

35:1 aspect ratio screw ensures uniform film and dense bubbles; optimized design cuts noise, boosts stability by 30%, and extends service life.

The biggest mistake is buying based on the lowest price alone. Here’s my practical advice:

Audit Your Real Needs: Be realistic about your required output (kg/hour). An oversized machine wastes capital and energy; an undersized one becomes a bottleneck.

Request a Live Demo: Always ask to see the machine run with your specific material blend, if possible. Watch for smooth operation and listen for unusual vibrations.

Plan for Support: Ensure the supplier provides comprehensive training and has readily available spare parts. A machine stuck waiting for a replacement part for weeks is a massive hidden cost.

While many machines can make bubble film, our core differentiator is durability and process stability. We use thicker gauge steel in critical stress points and industrial-grade components from recognized brands. This might mean a slightly higher initial price, but it translates to less unplanned downtime, lower maintenance costs over 5+ years, and a much more consistent product. You're not just buying a machine; you're buying production peace of mind.

Consistency is what separates an amateur setup from a professional one. Our machines achieve this through two main features:

Precision Temperature Control: Multiple independent heating zones with PID controllers ensure the plastic melt is uniform throughout the extrusion process.

Stable Film Formation: A balanced air ventilation system and calibrated rollers prevent air bubbles from collapsing or merging. This results in a roll of film where every square meter has the same protective strength and appearance, batch after batch.

Our machines are engineered for versatility. They primarily run on LDPE (Low-Density Polyethylene) resin, which is the industry standard. The good news is that they can handle a blend of virgin and high-quality recycled LDPE granules without clogging, allowing you to control material costs and meet sustainability goals. We strongly advise against using low-grade or contaminated recycled materials, as they can damage the extruder and compromise the strength of the final bubble film.

Don't just look at the power rating in kilowatts. That's like comparing cars only by engine size. The real key is the energy consumption per kilogram of film produced. A machine with a higher kW motor might be more efficient if it produces film faster and with less waste. Always ask suppliers for this specific data. In my shop, we've found that models with modern servo-driven motors and well-insulated heating barrels typically use 15-20% less energy, which adds up significantly on your monthly bills.

Our bubble film machines are designed for efficiency, with production speeds ranging from 50 to 150 meters per minute, depending on the model and bubble size. In practical terms, that translates to output of about 80–200 kg per hour for standard setups. Keep in mind, factors like material type and machine maintenance can affect this, so we always recommend consulting with our team to match the speed to your specific production goals for optimal results.

Industrial bubble film machine prices can vary widely, but you're typically looking at $15,000 to $50,000 or more, depending on features like automation level and production capacity. For example, a basic semi-automatic model might start around $15,000, while high-end versions with advanced controls can exceed $50,000. It's wise to get quotes from multiple suppliers and consider total cost of ownership, including installation and spare parts, to avoid surprises down the line.

Safety is non-negotiable, so always verify certifications like CE (for European standards) or ISO 9001, which cover quality and operational safety. In my years advising buyers, I've seen that machines with OSHA-compliant features or UL listings add an extra layer of trust. These certifications ensure the equipment meets essential guidelines for electrical safety and emission controls, reducing risks like overheating or operator injuries—crucial for maintaining a safe workshop environment.

When selecting a bubble film machine for high-volume needs, focus on output capacity, durability, and automation features. Look for models with high-speed extruders and reliable cooling systems to avoid downtime. I'd recommend checking the machine's hourly output (aim for at least 100–200 kg/hr for industrial use) and opting for brands known for sturdy builds. Don't forget to assess your space and power requirements—it's all about balancing speed with long-term reliability to keep production flowing smoothly.

The average return on investment (ROI) for a bubble film machine really depends on factors like usage frequency, energy costs, and local market demand for packaging materials. In my experience, many small to mid-sized operations see a payback period of 1–3 years, thanks to savings on outsourcing bubble wrap. For instance, if you're producing consistently, ROI can hit 20–30% annually—just remember to factor in maintenance and raw material expenses to get a clear picture.

A: If you encounter any issues, first check our online troubleshooting guide—it covers 90% of common problems. For unresolved issues, contact our technical support team via phone or email, and we'll respond within 2 hours. For major faults, we can arrange onsite repair (within 48 hours for domestic customers, 3-5 days for international clients). We also offer remote diagnostic services for quick problem identification.

A: We provide a 12-month warranty covering manufacturing defects for all bubble film machines. The warranty includes free replacement of faulty components (excluding wearing parts) and technical support. We also offer extended warranty plans (1-3 years) for additional peace of mind. Read our full warranty terms for more details.

A: Daily maintenance includes cleaning the heating roller, checking air pressure, and lubricating moving parts. Weekly maintenance should focus on checking the drive belt tension and electrical connections. Common wearing parts are the heating elements, sealing rollers, and cutter blades—we provide these as spare parts at factory prices. Get our detailed maintenance schedule to extend your machine's lifespan.

A: Power requirements range from 5.5kW (entry model) to 22kW (industrial model), with 380V three-phase electricity as standard (220V single-phase available for small models). Space-wise, you'll need at least 5m×3m for the machine itself, plus additional space for raw material storage and finished product handling. Contact us to obtain the complete technical specifications, precise dimensions, and required details.

A: Our bubble film machines come with detailed installation manuals and video guides. Basic installation (connecting power, air supply, and raw materials) can be completed in 1-2 days with 2-3 workers. Operation only requires basic training—most operators master the controls within a day. We also offer onsite installation and training service for an additional fee.

A: Yes, we offer customization based on your production requirements. Common customizations include: width adjustment (500-2000mm), special bubble patterns, double-layer production capability, and integration with existing production lines. Custom projects typically take 4-6 weeks. Tell us your specific needs and our engineers will design a solution for you.

A: The quoted price includes the main machine, control system, air compressor, and basic tool kit. Optional accessories (like auto-winder, edge trimmer, or thickness gauge) are priced separately. All machines come with a standard one-year warranty. Request a customized quote with your required accessories for an accurate price.

A: Bubble size selection depends on your packaging needs: 10-15mm bubbles are suitable for small electronics and fragile items; 20-25mm bubbles work well for medium-sized products; 30mm bubbles provide heavy-duty protection. Most of our machines support adjustable bubble sizes, and our technicians can help you determine the best configuration based on your specific products.

A: Our bubble film machines are mainly designed for LDPE (Low-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) raw materials. They can also handle recycled PE materials (up to 30% mixing ratio) with proper adjustment. Note that material purity affects bubble quality—we recommend referring to our material selection guide for optimal results.

A: Our bubble film machines have different production capacities based on models. The entry-level model can produce 50-100 meters per hour, while the industrial-grade model reaches 200-300 meters per hour. The capacity also depends on bubble size (10-30mm) and film thickness (0.03-0.1mm). <a href="/bubble-film-machine-models">Check the detailed specifications of each model</a> to find the one matching your production needs.

Expert pre-sales consultations & tailored solutions. 24/7 post-sales support & global spare parts network. Reliable partners for your machinery needs.

Shrink FAQAdvanced Technology

Our machines feature the latest technology, including precision extrusion systems and automated controls for consistent quality and efficiency.

R&D Excellence

Our dedicated R&D team continuously works on innovations to improve machine performance, reduce energy consumption, and enhance user experience.

Quality Control

We implement strict quality control measures throughout the manufacturing process to ensure our machines meet the highest standards of reliability and performance.