Effective troubleshooting ensures minimal downtime and consistent product quality. Below are common issues, their causes, and step-by-step solutions.

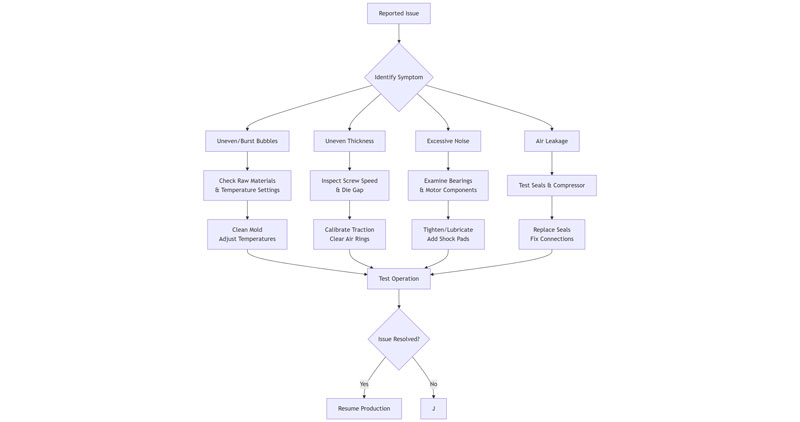

The flowchart below summarizes key troubleshooting steps for quick reference:

If issues persist after basic troubleshooting (e.g., control panel errors or mechanical jams), contact a certified technician to avoid further damage.

By combining systematic checks with preventive maintenance, you can enhance machine longevity and production efficiency. For complex issues, always refer to the manufacturer’s manual.