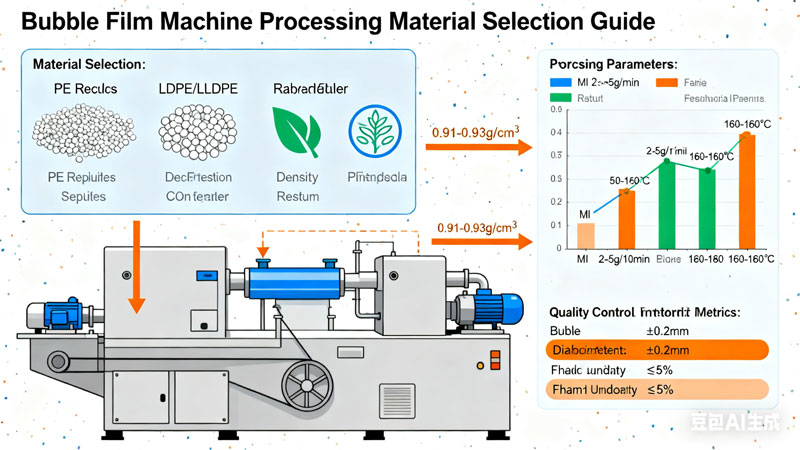

Bubble film production primarily uses polyethylene-based materials as the base raw material, each with unique properties:

In practice, blending ratios are commonly used to achieve optimal results:

When selecting materials for bubble film machine processing, consider the following factors:

For specific needs, consider these material modification methods:

Evaluate the appropriateness of material selection through the following indicators:

Selecting appropriate processing materials is crucial for ensuring bubble film quality and requires comprehensive decision-making based on product use, equipment characteristics, and cost considerations.