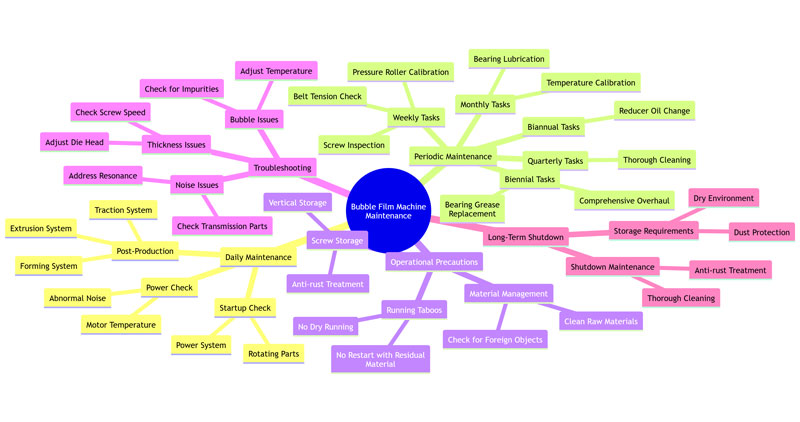

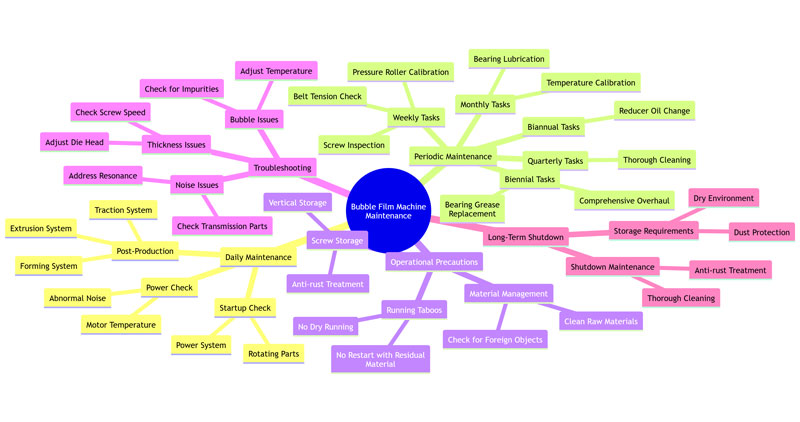

A comprehensive maintenance guide is essential for ensuring your bubble film machine operates reliably and has a long service life. Here is a structured guide based on best practices, covering daily, periodic, and long-term shutdown maintenance.

Daily Maintenance Checklist

Daily maintenance focuses on inspection and cleaning to prevent common issues before starting production.

| Task |

Component/System |

Key Actions |

| Pre-Startup Check |

Power, Vacuum, Pneumatic, and Cooling Systems |

Verify all systems are functioning correctly before powering on. |

| Post-Startup Check |

Rotating Parts |

Confirm all parts are rotating in the correct direction. |

| Extrusion System |

Screw and Barrel |

After production, purge residual molten material by feeding a small amount of raw material or cleaning compound. |

| Extrusion System |

Heating Coils/Electromagnetic Heaters |

Check for security and ensure they are free of oil stains, which can cause overheating. |

| Forming System |

Forming Rollers and Pressure Rollers |

Wipe surfaces with a soft cloth dampened with warm water or neutral detergent to remove film fragments. |

| Traction System |

Traction and Guide Rollers |

Inspect for scratches or sticky residue and clean promptly to prevent film tearing. |

| Power System |

Motor and Reducer |

After startup, check housing temperature (should not exceed 60°C) and listen for abnormal noises. |

Periodic Maintenance Schedule

Beyond daily tasks, a strict schedule for periodic maintenance is crucial for long-term equipment health.

-

Weekly Tasks

- Screw and Barrel Inspection: Check the screw surface for scratches and the barrel's inner wall for smoothness. Wear can lead to uneven plasticization of raw materials.

- Pressure Roller Calibration: Ensure pressure is uniform by comparing bubble sizes on both sides of the film. Adjust the cylinder or spring pressure device if uneven to avoid inconsistent thickness.

- Conveyor Belt/Chain Tension: Check tension weekly. Excessive slack or tightness can reduce efficiency or accelerate wear.

-

Monthly Tasks

- Temperature Sensor Calibration: Use an infrared thermometer to verify sensor accuracy (±2°C maximum error). Inaccurate readings can lead to energy waste or insufficient material melting.

- Bearing Lubrication: Apply high-temperature grease to the bearings of traction and guide rollers to ensure smooth rotation and reduce motor load.

-

Quarterly (Every 3 Months) & Biannual Tasks

- Thorough Cleaning: Perform a deep clean of the entire machine, including the die.

- Bearing Lubrication Replacement: Replace the grease on all bearings every three months.

- Reducer Oil Check/Replacement: Check the oil level in the reducer every three months and replace the lubricating oil every six months.

-

Long-Term (Every 2 Years)

- Complete Overhaul: Conduct a comprehensive inspection and overhaul of the entire equipment to address wear and tear that accumulates over time.

Key Operational Precautions

Adhering to these operational rules can prevent significant damage.

- Avoid Dry Running: Never run the extruder screw without material, as this can severely damage the screw and barrel.

- Proper Startup after Downtime: If the machine was shut down with material inside, you must heat all temperature zones to the specified requirements and maintain the temperature for over 30 minutes before restarting. Starting at a low temperature can damage components.

- Keep Raw Materials Clean: When feeding the hopper, ensure no metal debris, sand, or tools enter, as these can damage the screw and barrel. Stop immediately if you hear any abnormal sounds during operation.

- Proper Screw Storage: If the screw is removed from the barrel for a long period, hang it vertically to prevent bending or permanent deformation. Both the screw and barrel should be coated with anti-rust oil for protection.

Troubleshooting Common Problems

Here are solutions to some frequent issues

:

- Uneven or Burst Bubbles: Check for impurities or moisture in the raw materials. Screen or dry the materials accordingly. Also, measure and adjust the temperatures of the extruder and die head, and inspect the mold for blockages or wear.

- Uneven Film Thickness: Check if the screw speed is stable and ensure the traction speed matches the extrusion speed. Use the adjusting bolts on the die head to make fine adjustments to the gap while measuring the film thickness.

- Excessive Machine Noise: Inspect mechanical transmission parts like bearings for wear or lack of lubrication. Check the motor fan and bearing. Identify if the noise is from a specific part or due to resonance, which may require adding shock-absorbing pads.

Maintenance for Long-Term Shutdown

If the machine will be idle for an extended period, take these additional steps

:

- Thorough Cleaning: Clean the inside and outside of the equipment thoroughly to remove all dust, debris, and residual raw materials. This prevents impurities from causing damage when the machine is restarted.

- Rust Prevention: Apply anti-rust oil to critical components like the screw and barrel to protect them from corrosion during storage.

- Proper Storage: Store the machine in a dry, clean environment.

I hope this detailed guide helps you maintain your bubble film machine effectively. For machine-specific procedures, always refer to your equipment's official manual. If you encounter a specific issue not covered here, feel free to ask!