Bubble film is a packaging material made of transparent plastic with a large number of dense bubbles or cavities on the surface. They can effectively protect and cushion fragile items to avoid damage during transportation or handling.

1.Packaging protection: Effectively prevent falling and damage, suitable for fragile items such as glass products, ceramics, electronic products, etc.

2.Filling material: High-quality materials are used to fill the parcel box to prevent objects from colliding and moving.

3.Insulating material: Under special needs, bubble film can play a role in heat preservation, such as when refrigerated goods are circulated.

4.Shock-absorbing material: To ensure the safety of items, bubble film has good shock-absorbing properties and reduces the possibility of collision damage.

5.Mat or mattress: In emergency use, bubble film can be flexibly used as a temporary mat mattress to provide comfortable support.

Raw material preparation: First, transparent plastic materials need to be prepared, mainly polyethylene (PE) or polypropylene (PP). According to the specific needs of the bubble film, you can choose to add auxiliary materials such as plasticizers and antistatic agents.

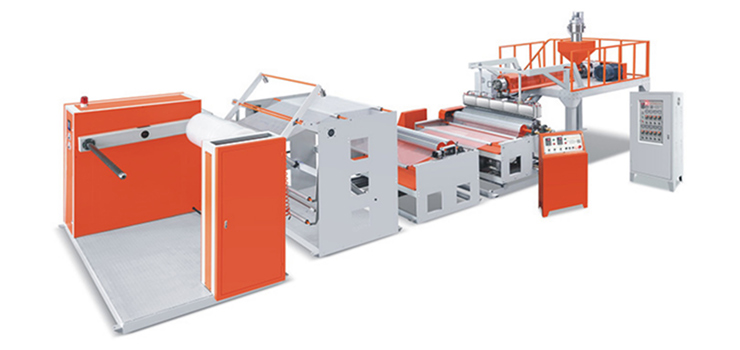

Extrusion molding: The prepared polyethylene raw material is heated and compressed by the extruder. During the extrusion process, the equipment temperature, extrusion speed, cooling water flow and other parameters are checked and adjusted in time to ensure product quality.

Processing and shaping: The extruded bubble film needs to be processed and shaped to achieve the required product size and thickness. The bubble film is passed through a vacuum forming roller, and countless bubbles are sucked out to form a bubble film structure.

Cooling and curing: The formed bubble film will pass through a series of cooling rollers or other cooling devices to quickly cool it and solidify it into a stable film.

Cutting and winding: The cooled bubble film will be cut into the required width and wound into a roll by a winding device.

Winding packaging: The cut bubble film product is wound through a winding device, and the wound bubble film is packaged using a roll winding device for easy transportation and storage.

The above steps are only the general process of bubble film machine production. The scale and function of bubble film machines will vary depending on the manufacturer and specific needs. Some machines may also be equipped with additional functions, such as automatic cutting and winding, bubble size and density adjustment.